Services

Details

Material-handling devices

Including cranes, derricks, fork-lifts, truck-mounted cranes, shackles, hooks, elevating platforms, and tele handlers.

Personnel handling devices

Such as elevators, escalators, ski lifts, cable cars and mobile elevating work platforms (MEWPs).

Our crane, lifting machinery inspection and identity can help you: entity lifting consulting & examination:

- → Meet all associated regulatory requirements, with independent inspection carried out in accordance with all applicable regulations, standards and engineering practices;

- → Assure the safe and proper working capability and condition of your lifting machinery equipment;

- → Maintain the capability and availability of your equipment;

- → Maximize uptime and planned outages to minimize operational impact.

Trusted crane, hoisting and lifting equipment inspection from a leading supplier

Cranes have become an integral part of many industrial operations. Their proper functioning is ensured through crane surveying in connection with industrial surveying and measurement services. Cranes are subject to very heavy loads and due to this continuing strain can be subject to wear and tear that may impact their functionality and their safety. Even very small geometric deviations can have an impact on the wear experienced by other components. To handle this, we offer full services in the field of crane surveying using the latest technology.

As a leading supplier, we are accredited to perform conformity assessments, as well as statutory and voluntary inspections on cranes, hoisting and lifting equipment across the world. Plus, we can also provide training for operators of cranes and elevating platforms in accordance with local and international standards.

Crane, Hoisting and Lifting equipment

Our crane, hoisting and lifting equipment inspection services include:

- → Checking of brakes, clutches, sheaves, and wire rope assemblies;

- → Design studies and calculation reviews;

- → Dynamic and static load testing;

- → Inspection of all the structural load bearing members, including sheaves;

- → Checking crane girders, rails and columns of overhead cranes to assure structural integrity;

- → Line level and span crane gantry surveys;

- → Operational tests to assure that your unit is functioning properly;

- → Periodic inspections and inspection prior to use of mechanical, structural, electrical, and safety systems, as well as of wire ropes and chains;

- → Re-examination of all safety devices;

- → Regulatory compliance assessments;

- → Remnant life assessment;

- → Repairs supervision.

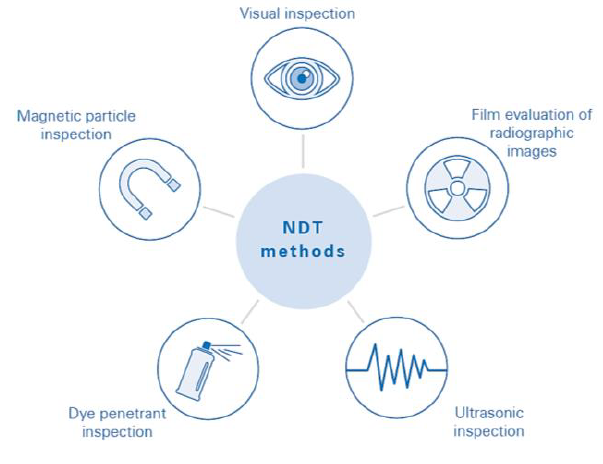

Non-Destructive Testing is yet another division of African LME

With over many years of experience across the industry, our technicians are qualified to level 2 in accordance with the requirements of ASME, BS, EN.

We provide Non Destructive Testing services in the following disciplines:

-

Eddy Current test: Eddy current testing is one of several non-destructive testing methods that uses the electromagnetism principle for flaw detection in conductive materials. A specially designed coil energised with an alternating-current is placed in proximity to the test surface, generating a changing magnetic field that interacts with the test-part and produces eddy currents in the vicinity, used for the listed purposes below:

- Flaw detection;

- Material and coating thickness measurements;

- Material identification;

-

Heat treatment condition of materials.

-

Industrial Surveying (Integrity testing): Industrial surveying and measurement is becoming more and more significant. As technical progress continues, the requirements for measurement systems and for precision in plants and machines are increasing all the time. In most areas of machine and plant construction as well as in production processes, the tolerances for deviations from standards are becoming more and more strict. Most tolerances are now less than one millimeter. The reliability of turbines, production lines, cranes and other machines are a top priority not only as an aspect of quality assurance but also to guarantee safety. Key tolerances must be measured and monitored with highly precise measurement devices.

The measurement instruments and measurement methods that we use are adapted exactly to your requirements and the objects and elements that are to be measured to provide the client with precise results that are required o the activities below:

- Measurement and surveying of electrical substations

- Settlement measurements

- Plant measurements

- Reverse engineering

- Pressure Test;

- MPI - Magnetic Particle Testing (Colour contrast and fluorescent);

- MFL - Magnetic Flux Leakage (Tank floors etc.);

- UT - Ultrasonic Testing;

- Flaw Detection;

- Thickness Testing;

- Continuous scanning of vessel and tank shells;

- RT - Radiographic Testing: Radiographic inspections for welded components in all industries using various techniques in accordance with BS, EN and ASME codes;

- LPT - Liquid Penetrant Testing (Colour contrast and fluorescent);

- Hydraulic and Pneumatic Testing - As an inspection authority, African LME advises and makes recommendations on the hydro testing of any pressure equipment such as air receivers, pumps and portable compressors.

A technical failure in a substation could result in a power failure for entire cities or regions. For electricity suppliers this can entail income losses and damage to public reputation. To avoid such negative consequences, we support utility companies with surveying for electrical substations, design plans and construction activities and can also provide control measurements with 3D laser scanners on a long term basis.

Settlement measurements are particularly significant for heavy building structures and construction elements. Through their heavy weight or through vibrations the foundation earth can be deformed over time which may cause structures to sink. With settlement measurements planned from the start, it is possible to take preventive measures should settlement occur so that damages and loss of income are avoided.

Monitoring plant installations and components is also part of our comprehensive services in the area of industrial surveying and measurement. Over time, ongoing motions can result in wear and tear that may in turn cause deformations which can have a negative impact on plant operation. We provide exceedingly exact measurement results.

With reverse engineering measurements and visualizations are used to go from the finished product to a 3D model which provides information about individual components. The highly precise 3D model is generated using 3D laser scanning. With discrete reconstruction of all surfaces, a precise CAD model is prepared as all surfaces are necessary for effective modeling. With this type of reverse engineering process, the specific dimensions of prototypes can be captured, for example. This makes it relatively simple to visualize and reproduce missing design elements.

Training

We have well Trained Mozambique Instructors that can speak both English and Portuguese. Assessors were trained in South Africa by a TETA representative.

Equipment Operators of all Industries, such as, mining, manufacturing, retail Farming, factories and any company or person that use and operate lifting or earthmoving equipment.

We offer certification on:

- Basic Rigging Courses, (site specific);

- Basic Firefighting;

- First Aid courses: Level I; Level II; Level III;

- Forklift Operators;

- Front End Loader;

- General Risk Assessment;

- Glif Battery Car;

- Hencon Plant Specific Equipment;

- Mobile Crane Operators;

- Mobile Elevating Work Platform courses (JLG / Cherry Picker and Scissor Lift);

- Overhead Crane Operators;

- Safety Personnel Training Programs;

- Safety Harness application courses;

- Tractor/ Trailer;

- Tractor Loader Backhoe (TLB);

- Tree Felling Operator Training;

- Truck Mounted Cranes;

- Vehicle Driver Training, including 4x4 courses and assessment on drivers;

- Working at Heights Course.